High Performance Side Entry IML Robot

Robot Specification

| # | Name | Value |

|---|---|---|

| 1 | Suitable IMM | 150-650 |

| 2 | In Mold Time | 0.8~3 |

| 3 | Dry Cycle Time | 2s |

| 4 | Power Input | AC220V/3P |

| 5 | Working Pressure | 5~7 |

| 6 | Air Consumption | 10 NL/Cycle |

| 7 | Power Consumption | 8.5 kW |

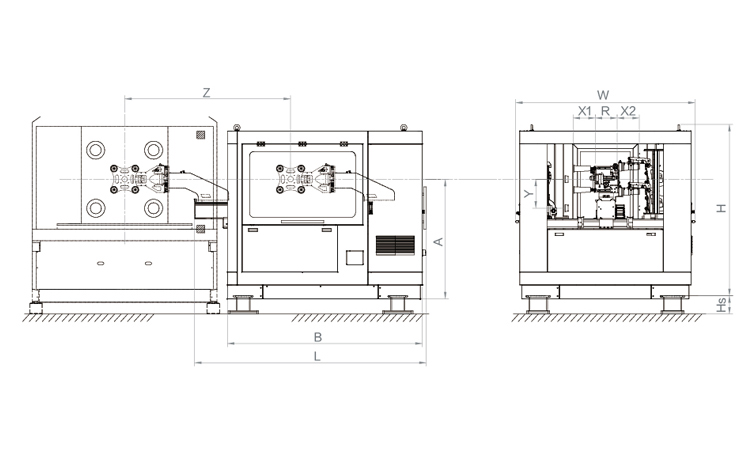

Installation Dimension

| # | Name | Value |

|---|---|---|

| 1 | X1 | 190 mm |

| 2 | X2 | 190 mm |

| 3 | Y | 400 mm |

| 4 | Z | 2100 mm |

| 5 | L | 2730 mm |

| 6 | W | 2410 mm |

| 7 | A | 1280 mm |

| 8 | B | 2260 mm |

| 9 | H | 1720 mm |

About SW8 Series IML Robot

SW8 Series IML robots is an IML Robot family launched by SWITEK Automation which include the SW831 custom made for the production of IML Lids; SW833 for small and medium sized Lids/Container IML production and SW850 for extral large size containers IML production. Since its first showcase in Chinaplas 2009, SW8 Series IML Robot had now been one of the most popular side entry IML Solutions among the world IML package producers.

Features of SWITEK SW8 Series IML Robot

The withstand the demands of high-speed production environments and ensuring stability and longevity, a sturdy frames made of square tube with gross weight up to 1500kg is designed to esnure a 0 change of the IML robot position during fast production.

The manufacturing of the SWITEK SW8 Series IML robotic adhere to European safety standards in both mechanical (Safe-door with cross emergency stop) and electrical (CE with strict EU12/EU67 interface wiring) design to ensure safe operation and minimizing risks.

The suction cups and the conveyor for the SW8 series of IML robot of which the containers is touching are made from food-grade materials and hygienic considerations to make them suitable for use in the food packaging industry.

SWITEK SW833-S6 series of IML robot are designed for the fast production small and medium size thin-wall IML containers. In K-Show

2019, it worked with the Yizumi P250 high speed injection molding machine showcased a turn-key solutions of 4 cavities butter cups

high speed IML production at the total cycle time of 2.1s with an in mold time of only 0.8s.

SWITEK 4 Cavities Butter Cups Side Entry Solutions at 2.1s Showcased at K-Show 2019

For SWITEK SW8 series of IML robots, we choose Panasonic A6 series of servo motor driver and servo motor work with the THK linear motion guides to ensure a stable fast moving of the axis. And quality brand of Pneumatic components and sensors to ensure the overall reliability and stability of the IML robot.

With excellent system design and assembly craftsmanship, the repeat positioning accuracy of the SWITEK SW8 series of IML robot can be up to ±0.1mm to ensure the consistent and precise IML label placement.

The sturdy frame design and the use of quality components ensured the long service life of the SWITEK SW8 series of IML robot. And for buyers of SWITEK IML robot will have life long FREE online technical support from experienced service engineer to ensure the unstop running of the IML system.

With modular design, the SWITEK SW8 series is suitable for the fast IML production of both lids and containers of a food package, the paint buckets or the IML production of a household products.

With a fast cycle time and competitive cost, the SWITEK SW8 series of IML robot will help the IML system investors to get their cost revovery in around 8~10 months after the system start up. And the IML robot could be integrated into an automated IML package production line easily.

The SWITEK SW8 series of IML robot are designed to be easy integration to an automation system say an IML production system with

IML robot, the vision control system and the packing system to unmanned IML production of the IML Yogurt package or have an alternative

design of the IML robot to assemble the buckets handles automatically to reduce the labor costs.

SWITEK 2 In 1 IML Solutions with Vision Control and Packing for Yogurt Cups IML Production 2 Cavities Buckets Side Entry IML Solution with Handle Assembly 12+12 Side Entry IML Solutions for Lids with Spoon Assembly

Compared to manual labeling, the IML robot can significantly increase prdouction speed and output.

With a repeatability up to ±0.1mm, the SWITEK SW8 series of IML robot will produce a consistent cycle time and precise IML label picking and placement to reduce the scrap and material waste.

SWITEK R&D team will design the IML robot according to the size of the injection molding machine to make the IML robot compact and space-efficient to make it beneficial for factories with limited space.

As one of the Key Manufacturers of IML Robots in China, SWITEK will deliver more than 300 sets of IML system for the IML packages producers around the world with a supply capacity up to 35 sets of IML robot per month. We'll also provide a turn-key solution of IML for global clients to ensure that the IML system received is ready to work to reduce your system purchasing risk and cost.

Contact SWITEK IML

sales06@switek.biz

+86 186 5927 5869

DongGuan, GuangDong, China

HuangYanZheng©Copy Right