sales06@switek.biz

+86 186 5927 5869

Company Profile

- Date of Founding: 2006

- Headquarter: DongGuan City, GuangDong Province

- Address: Nanwei Industrial District Chashan Town Dongguan City Guangdong Province China

- Tel: + 86 186 5927 5869

- E-mail: sales06@switek.biz

- Website: https://www.switek.com.cn

-

Main Business:

- The design & manufacturing of SWITEK brand industrial robot for injection automation

- The design & manufacturing of SWITEK brand IML Robot

- Injection Automation System Integration

- The OEM/ODM production of industrial robot for injection automation

- The OEM/ODM production of IML Robot

- The OEM/ODM service of injection automation solutions integration

The History of GuangDong SWITEK Technology Co., Ltd.

- 2006 -- ShenZhen Wetec Technology Co., Ltd. The first injection robot (SW2 Series) was put on market.

- 2008 -- The first 3 axis servo injection robot was put on market

- 2009 -- Moved to Dongguan and renamed the company name "DongGuan Weltec Injection Automation Co., Ltd." with the first SW8 Series IML robot put on market.

- 2011 -- Put on market the SW6 Series European style 3/5 Axis Servo Injection Robot

-

2013 --

- New Brand Name "SWITEK" with ultra new logo "SWITEK"

- Put on market 64 cavities forks folding system SW818

- Recognized as the "National High Tech Enterprise"

- The Certificate of "ISO 9001"

- 2015 -- Start a Joint-stock reform and renamed the company to "DongGuan SWITEK Technology Auotmation Co., Ltd. "

- 2016 -- Listed in the New OTC Market with stock code : 838363

-

2017 --

- The National Invention Patent -- High Speed Side Entry IML Solutions

- Recognized as the R&D Institude of the Industrial Robot and Automation Application in DongGuan City

- SMEs Certification of SWITEK High Speed Side Entry IML System

- 2019 -- Renamed "GuangDong SWITEK Technology Co., Ltd. "

-

2022 --

- Introduced the new SWITEK VI System

- Awarded "The Top 100 Innovative Enterprises of DongGuan City"

- Acknowledged as "The Specialized, Refined and Innovative Small and Medium-sized Enterprise (SMEs)"

Robots & Automation Solutions

Honors & Certificates

- July 2013 -- Certificate of National High Tech Enterprise

- Certificate of ISO 9001:2015

- Certificate of CE

- 11 Consecutive years from 2013~2023 Certificate of GuangDong Province Contract Abiding and Credit Valuing Enterprise

- Science and Technology Small and Medium-sized Enterprise Technology Innovation Fund Project Certificate for High Speed Side Entry IML Solutions

- August 2016 -- Listed on OTC Market in the Field of Intelligent Manufacturing with Sotck Code: 838363

- Year 2016 -- Teaching Internship Base of Yangtze University

- Year 2017 -- DongGuan Industrial Robot and Automation Facilities R&D Center

- Year 2022 -- Membership Enterprise of NBPMIA

- Year 2022 -- Top 100 Innovative Enterprises in DongGuan

- Year 2022 -- Specialized, Refined and Innovative Small and Medium-sized Enterprise (SMEs)

Patents of Innovation

- Cutlery Packing Automation Solutions-- National Initiative:The first company to provide cutlery single pcs bag packing, multi-pcs bag pack, multi-pcs box packing injection auotmation solutions. Patent of Innovation: Cutlery Injection and Packing Automation SystemZL201510767484.7; Patent of Utility Model: Cutlery Box Packing Automation System ZL201821646402.9; Stack Mold Cutlery Side Entry Picking and Packing Automation System ZL201621033113.2; Cutlery Auto-collector ZL201420214055.8; Cutlery Single pcs Bag Packing System ZL201621033039.4; Cutlery Box Packing System: ZL201821646344.X; Cutlery Packing Control System V1.02018SR442082)

- Pipe Fittings Injection Automation Solutions -- National Initiative: The first company to provide a turn-key solution of pipe fittings part picking, in mold insertion, quality inspection, runner cutting automation solutions.( Patent of Innovation:Elbow Pipe Fittings Nut Inspection, sorting and feeding system ZL201610786859.9 Patent of Utility Model: Pipe Fittings Runner Cutting System ZL202020091447.5 ; Pipe Fittings Nuts Sorting System ZL202020091449.4 ; Pipe Fittings Nut In Mold Insertion System ZL201720977378.6 ; Pipe Fittings Runner Cutting SystemZL201720976469.8 )

- Closures Injection, Cooling and Inspection Automation Solutions-- National Initiative: The first company to provide turn-key solutions of closures picking, cooling, inspection and packing solutions( Patent of Utility Model: Closures Lining up and stacking automation systemZL201921622538.0 ; Closures lining up system ZL201921622526.8 ; Spoon and lids auto-assembly system ZL201922473119.1 ; High speed spoon sorting and spoon/lids auto-assembly system ZL201921623010.5)

- IML Solutions--National Iniative:The first company to proivde turn-key solutions of IML parts picking, visual control and packing solutions( Patent of innovation:High Speed Side Entry IML Solutions ZL201410176348.6 IML; IML Robot and IML Parts Picking Solution ZL201610797925.2; Patent of Utility Model: IML System Testing Facilities ZL20191622839.3;High Speed Servo IML Label Feeding System ZL201520332811.1 ; IML Servo Stacking System ZL201520332946.8 ; IML Labeling and Parts Picking Robot ZL201621033817.X ; High Speed Side Entry IML System V1.0 2018SR443462 )

- Cutlery Picking and Folding System -- National Iniative: The first company fto provide 64 cavities foldable forks picking and folding solution( Cycle Time 7.8S)(Patent of Utility Model: Foldable Parts Folding Automation Systeme ZL201721521116.5 ; One Folding System ZL201721536299.8)

Our Partners & Suppliers

Tips About Pipe Cutlery Injection Robot Selection

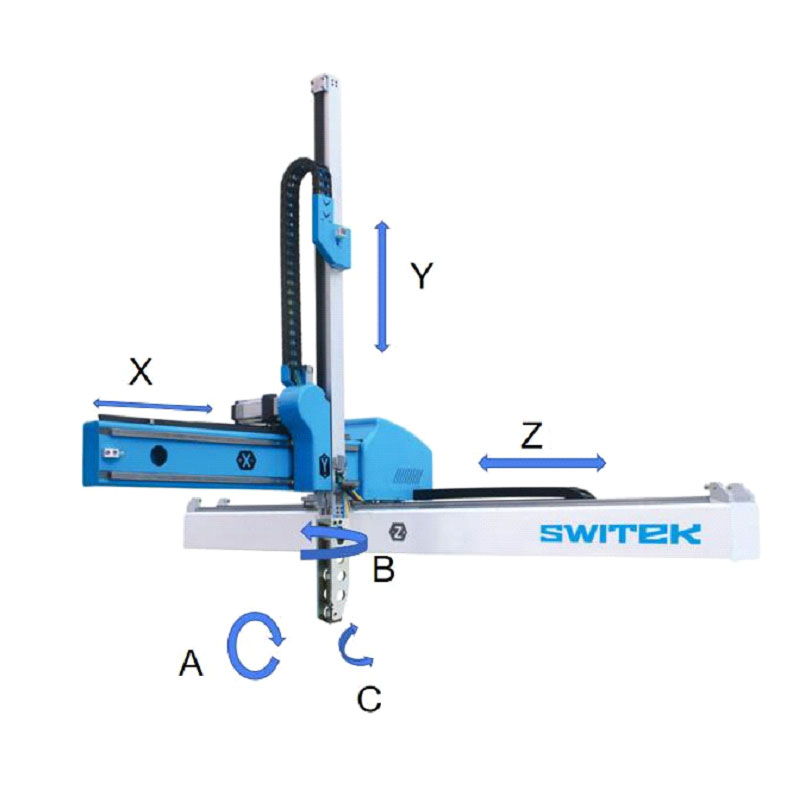

Axis Definition

Tips: To select a suitable injection robot for your cutlery injection project, the speed and the cavities of the mould would be the key parameters for a selection of a suitable robot. The more of the mold cavities, the larger would be the size of the EOAT and which means an increase of the robot size and payload. Especially for an cutlery production system of multi-pcs box/bag packing.

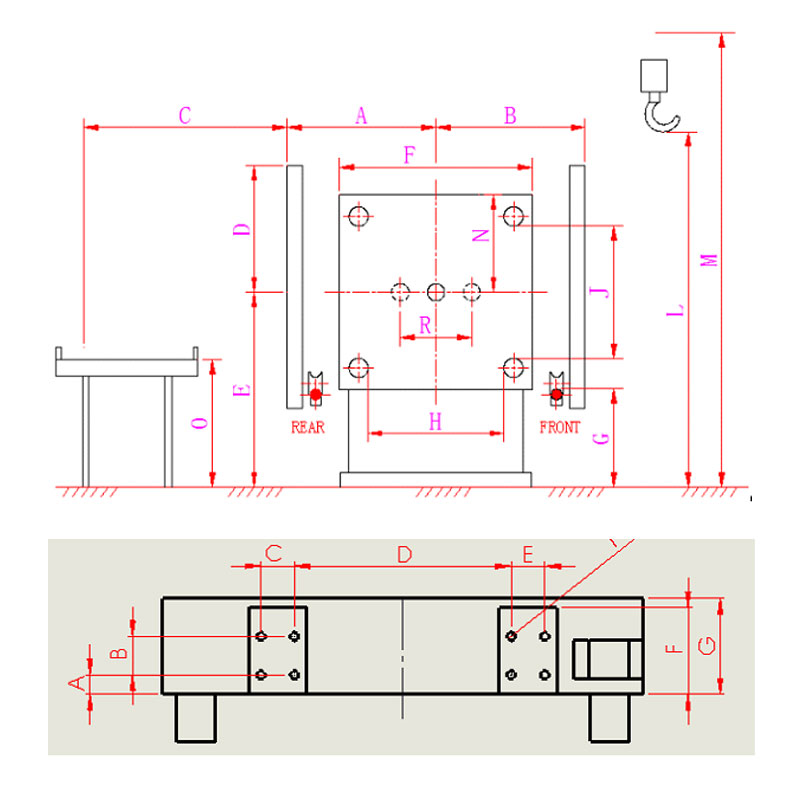

Robot Sizing

- L: The max length of the robot

- Z: The max distance where the parts to be dropped

- Y: The max distance movabel of the robot arm from the standby position to the mold center

- W: The width of the robot

- H: The height of the robot

- Hs: The height of the robot stand

- YM1: The height from the standby position to the top of the machine

- YM2: The distance from the Machine top to the mold center

- X1: The max distance of the main arm from the mold platen

- X2: The working stroke of the main arm

- X3: The Min distance between the main arm and the sub arm of the robot

- X4: The Max working stroke of the sub arm

- X5: The Min distance from the sub arm to the mold platen

Robot Installation

- A -- Non-operator side installation of the robot

- B -- Operator side installation of the robot

- L -- The height of the crane

- E -- The distance from the floor to the mold center

- G -- The distance from the floor to the safe door rail

- N -- The height from the top of the injection molding machine to the mold center

- H/J -- Distance between the tia-bars

- The Height of the Safe Door -- D-N

Tips: The primary principle of selecting a robot for your injection automatio project is that to make sure:

- Picked: The robot arm can reach the mold center to pick the parts

- Pickable: The robot has sufficient payload to carry the parts + EOAT

- Pick out: There's enough in mold space to pick the parts out

- Placeable: The parts can be carried over the safe door of the injection molding machine

- Speed: The robot must be fast enough to match the injectio cycle

- Arms: Choose single or double arms according to the mold type

- Arm Type: Choose standard or telescopic arm according to the height of the crane

- EOAT: For complex structure plastic parts, a set of custom made EOAT would be necessary

- Special Requirement: For the robots to be integrated into an automation system, some special requirements would be requested, a custom made robot would be in this case

Q & A About A Cutlery Packing Automation System

-

Will a cold runner cutlery mold suitable for an auto-packing system?

There're two kind of cold runner molds for cutlery:

The standard cold runner mold which the cutlery would be picked out with the runner, for this kind of mold it's not suitable for an auto-packing solution because of the unpredicatable deformation of the runner, it'll make the successful cutting of the runner impossible.

The cold runner mold with submarine gate, for this kind of mold it's possible to seperate the cutlery from the runner in mold before robot picking, it's suitable for an auto-packing system, and most of the low budget cutlery auto-packing systems now are based on these kind of mold. It's an econonic solution of cutlery auto-packing system.

-

Round mould layout or rectangular mold layout?

Again it'll depends on your budget and your technical team:

A round layout mould have a better runner balance but it's not friendly to a gantry robot to remove the well stacked cutlery to the packing machine, it means a more complex stacking system or have an articular robot to carry the well stacked cutlery to the packing machine.

A rectangular layout mould is friendly to a two gantry robots cutlery packing system and most of the low budget cutlery packing system is based on this kind of mold design.

-

Will there ba a auto-pcking system suitable for the packing of knifes, forks and spoons?

The sharing of one automation system for different products is the common expectation of many small and medium producers of cutlery, but it's not easy to make it come true because of the different shape between these products. The solution is to make an independent collecting station and EOAT for each products and have them replaced in every mold changing.

-

For a cutlery packing automation solution, what information to be provided to ensure a success of the project?

For a cutlery packing automation system, the information what we need would be:

- The layout drawing of the mold

- The 3D drawing of the cutlery

- The details of the injection molding machine

- How do you want the cutlery to be packed

- The total cycle time

PS: If you have any other questions about starting up a cutlery packing automation system, please feel free to send us an e-mail or contact us by Wechat/Whatsapp for instant communication.

Request for Quotation Now

Email: sales06@switek.biz